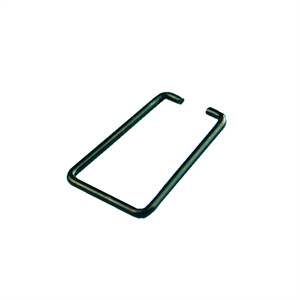

Square Wire Forming Spring Manufacturer

Square shaped wire spring, also known as rectangular spring, is a spring made from square or rectangular cross-sectional wire. Compared with common circular wire springs, square wire formed springs have some unique properties and applications.

Firstly, due to the design of square or rectangular cross-sections, this type of spring has higher stiffness under the same spatial conditions. This means that when it is subjected to external forces, the force generated per unit displacement is greater, so it can withstand larger loads. In addition, the square wire shaped spring also absorbs more energy, its characteristic line is closer to a straight line, and its stiffness is closer to a constant, which makes it have better fatigue resistance.

Secondly, the elasticity of square wire shaped springs mainly comes from rectangular section steel plates, which makes them have high load-bearing capacity, stability, and durability. In the automation industry, rectangular springs have a wide range of applications, such as providing stable support and recovery force to ensure the normal operation of equipment. In addition, due to its rectangular cross-section, the force area of the spring increases, resulting in a more uniform distribution of load, which can improve material utilization and durability, and reduce production risks caused by the use of inferior springs.

In terms of production technology, the manufacturing process of square wire shaped springs is similar to that of circular wire springs, including spring design, material preparation, tensioning, winding, heat treatment, surface treatment, and testing and testing steps. However, due to the special shape of square wire, specific machines and processes need to be used during the winding process to ensure the accuracy and quality of the spring.

Wire Forming has a wide range of applications, including but not limited to the following:

automotive industry

Fabricate frame and spring components for automotive seats. Various springs, snap springs and hooks inside the engine. Wire forming parts in suspension system of automobile chassis.

Electronic industry

Connector pins and spring contacts inside computer and phone. Fixing and supporting structures of wires and cables.

Medical field

Various clamps, hooks and elastic parts in medical devices. Handle and operating parts of surgical instruments.

Furniture Industry

Spring support structure for sofa and chair. Supporting and connecting parts of bed frame.

Building and Construction

Steel mesh for concrete reinforcement. Connections and Supports in Building Structures.

Manufacture of machinery

Various shaft pins, snap springs and hooks in industrial machinery. Springs and wire formed shock absorbing components in the drive train.

sporting goods

Springs and support parts in exercise equipment. Connectors and structural members of motion equipment.

Daily necessities

Wire forming parts in hangers, clips and other household tools.

Energy sector

Some wire forming parts in wind power plants. Installation and fixing structure of solar panel.

Wire Forming plays an important role in many areas, providing critical structural and functional support for a variety of products.