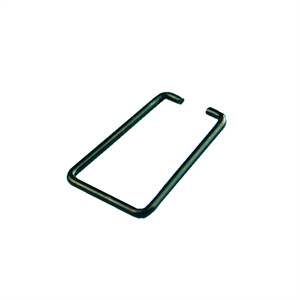

Constant Force Spring Spiral Spring

These constant force spring, Spiral Spring and power springs are of the same family and differ only in operation from a single pull, like a tape measure, to a counter balancing of two combined springs, which give a smooth and constant pull. These springs require sophisticated design engineering and we run computer software on each requirement to ensure the validity of your design.

Constant force spring offer high force output with very small space requirements, provide long linear reach with minimal force buildup, and store power indefinitely when extended. These precision springs are ideal for a wide variety of applications where constant force is needed,including applications requiring smooth returning and retrieving, counterbalancing applications, and tension and loading applications.

Because there are a number of different spring design possibilities for a given application it is suggested that you consult with a Fourslide Battery Contact engineer early in the design phase.

Capabilities of Constant Force Spring Spiral Spring:

Up to 5mm strip material in many widths & thickness.

Materials of Constant Force Spring Spiral Spring:

Constant Force & Power Springs are manufactured from a wide variety of materials including carbon steel and stainless steel and many others.

Equipment of Constant Force Spring Spiral Spring:

State of the art constant force machines

COMPRESSION SPRINGS are open-coil helical springs wound or constructed to oppose compression along the axis of wind. Helical Compression Springs are the most common metal spring configuration. Generally, these coil springs are either placed over a rod or fitted inside a hole. When you put a load on a compression coil spring, making it shorter, it pushes back against the load and tries to get back to its original length. Compression springs offer resistance to linear compressing forces (push), and are in fact one of the most efficient energy storage devices available.

An extension spring is the opposite of a compression spring, as push now becomes pull. Like compression springs they come in a variety of shapes and sizes. One of the most critical factors with these extension springs is the design of the hook. If done incorrectly, this can result in failure.

At Fourslide Spring & Stamping we use special computer extension spring design software on every application to ensure proper spring life and design correctness.

The most recognizable torsion spring can be found in a mouse trap. Its ends are rotated in angular deflection to provide forces of applied torque. They can also be designed to provide compression and torsion together.

Capabilities of Springs:

diameter to 20mm diameter, thick to 5mm flat strip

Materials of Springs:

Springs are manufactured from a wide variety of materials including music wire, hard drawn, oil tempered, galvanized wire, stainless steels and phosphor bronze, as well as exotics such as pre plated materials (gold, silver, tin) inconel, chrome vanadium and many others.

Equipment of Springs:

State of the art CNC wire forming capability as well as conventional spring coiling machines.